Built To Win | The all-new Colnago V4RS

In Colnago's words, "it is hard to improve what is already great." Colnago needed an evolution, rather than a completely new design. They had one goal - to ensure that the successor of the V3RS was built to do one thing... WIN.

October 2020 - New Bike Design Started:

Developed with the team Since day 0. Colnago are always in contact with the UAE Team Emirates,

and nowadays the UAE Team ADQ, receiving their

feedback and understanding their challenges. By listening to them, Colnago clearly understand what is

needed to create a winning product. While the V3Rs was winning the Tour, Colnago were already

thinking about the next Colnago superbike.

April-October 2021 - First Internal Prototypes Produces:

Not only performance. A touch of Colnago is needed. In the development phase, the aesthetic and functional

developments have gone hand in hand. Colnago is known for the beauty of its products.

The new bike must not only be functionally performative,

but also be extremely polished and refined in the look. Effort to use less paint on the frame to decrease overall

weight. C68 had a key role in the development of this frame.

October 2021 - Design Selection & Tests:

Thanks to the work done on the modular parts of the

C68, Colnago were able to study, test and optimize different

solutions for each part key part of the future

monocoque frame. In October we carried out the tests for UCI approval of

the Colnago Prototipo. We started preparing a small number of versions of the

bicycle that would differ only by the carbon frames

layups.

May 2022 - UAE Team Receive Bike:

Colnago sent the first Colnago Prototipo

to Tadej Pogacar in May 2022. He tested a no-brand version

on the roads of Tour de France. Ahead of such an important event the decision

was up to him: stick to a “safe” choice - racing

with the Colnago V3Rs - or risk using

a totally new prototype bike. We all know what the decision was.

July-October 2022 Prototipo Race Validation:

First Slovenia, then all-in for the Tour de France. Colnago had a limited number of Prototipo frames, they left open choice to the athletes whether to use the

Prototipo or the proven V3Rs.

ALL the team riders chose to use the Prototipo in races. Colnago didn’t have enough.

The riders who sticked to the V3Rs took this choice out of

material shortage, all the others rushed to try and race the

Colnago Prototipo.

Results:

After 4 months of use, the Prototipo accumulated 23 victories by 10 different riders, along with 28 podiums by 14 different riders - a bike that has now been unveiled to us as the Colnago V4RS.

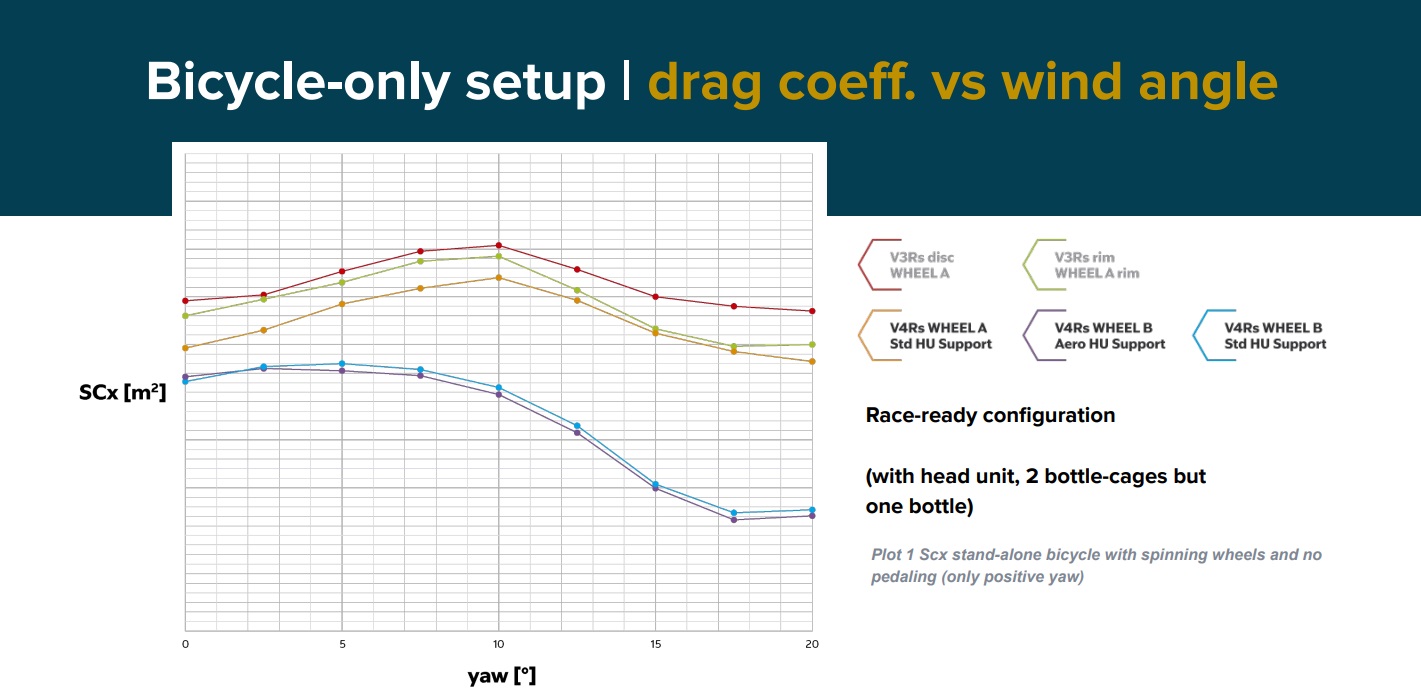

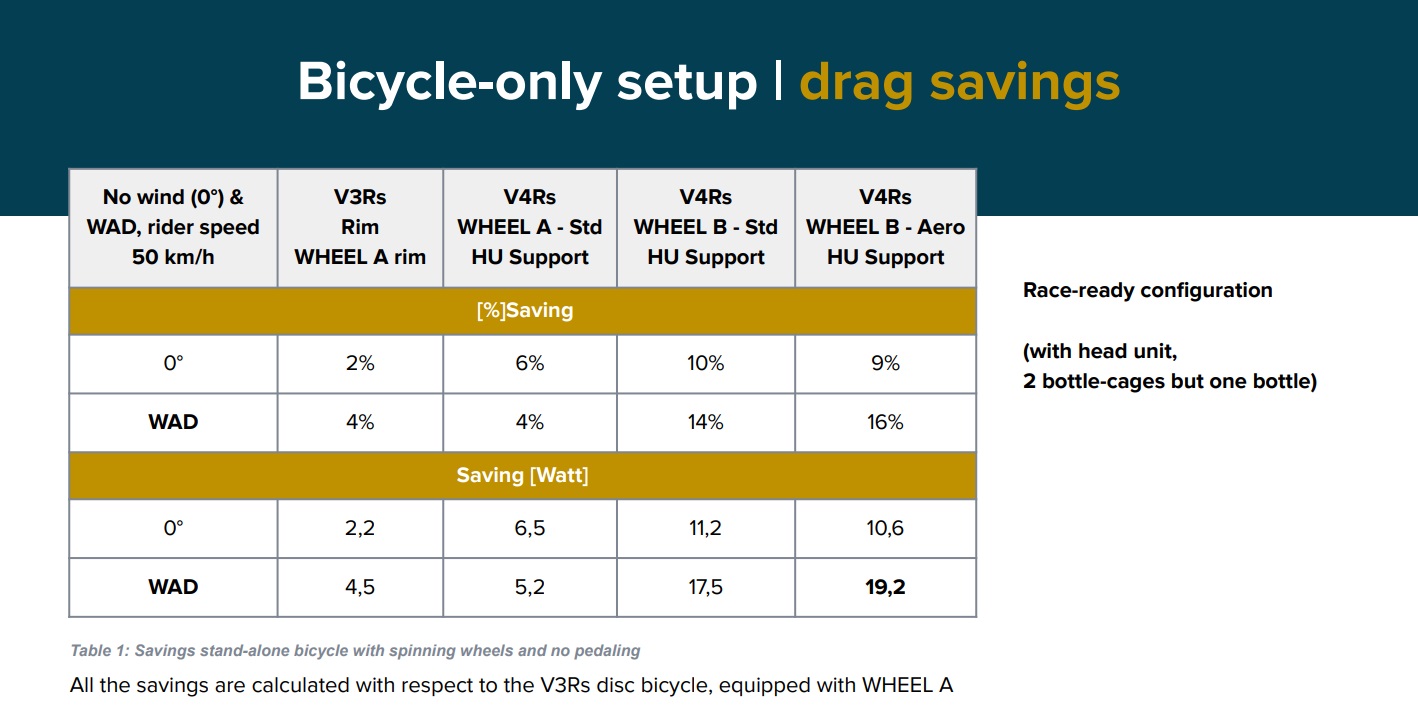

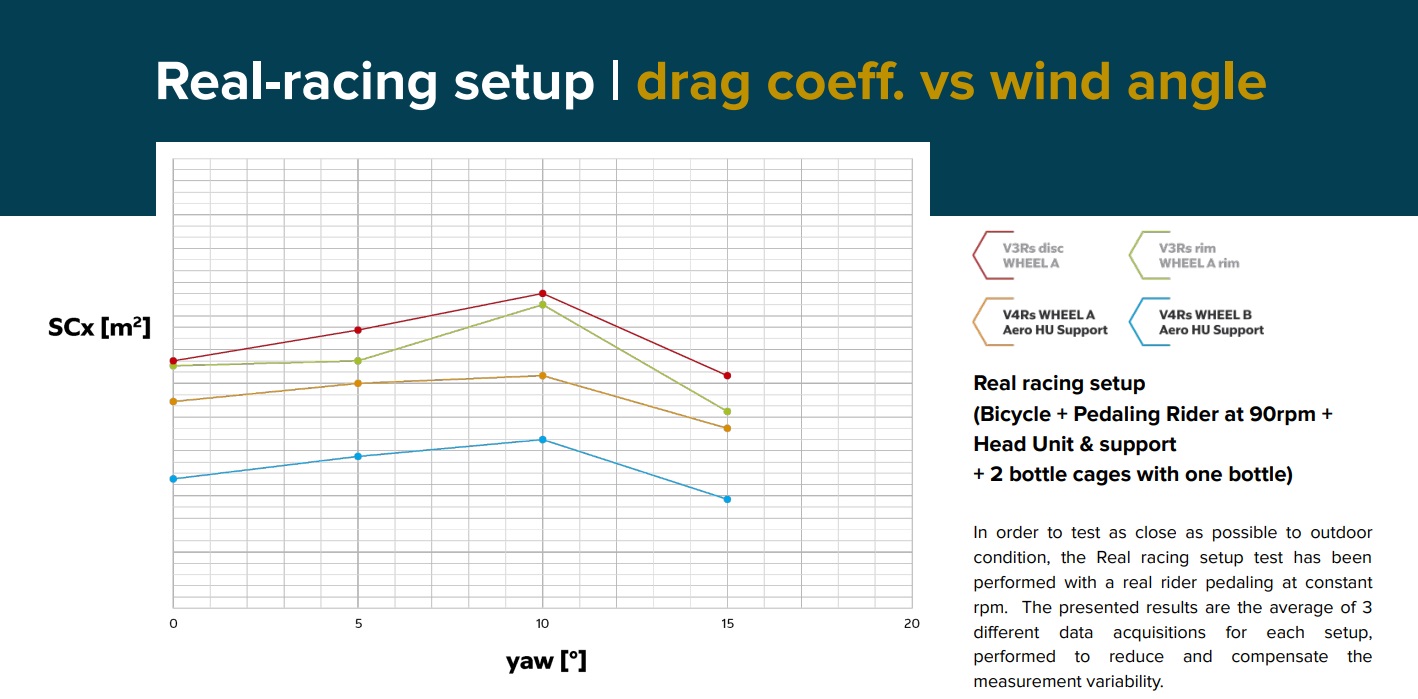

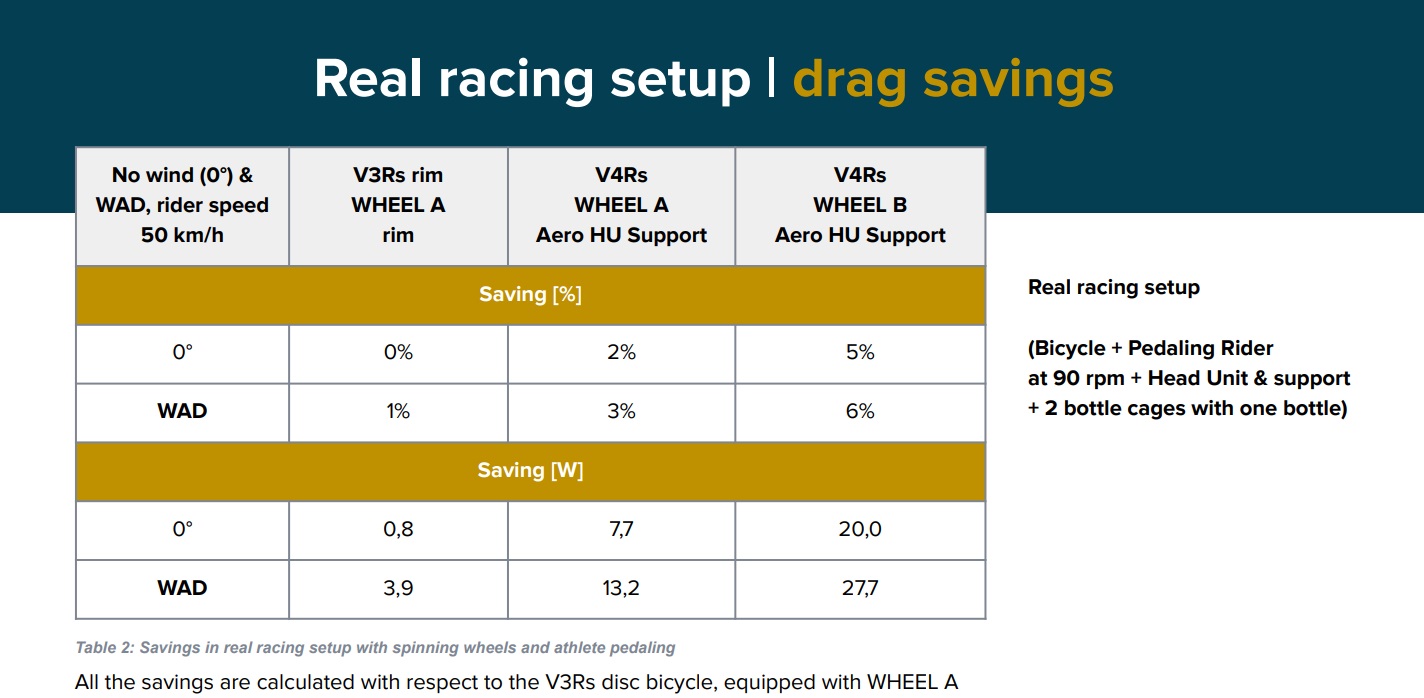

Aerodynamics:

The V4Rs has been conceived as a fully-integrated

system. While working on the aerodynamics in order to

reduce the overall drag, the superimposition of effects

simply doesn’t work. All the components must be

developed and tested together in order to state the

overall benefits. That’s why all the presented data is

obtained with the bicycle in race-ready configuration,

which means that it is equipped with head unit, 2

bottle-cages but one bottle only (as in the crucial race

phases).

Drag Reduction:

This process of design and development started from

the bike frontal area, which has a huge impact on the

drag, both directly (A factor in the formula) and through

its shape, by affecting the overall Cd factor.

Optimised Frontal Area:

The optimization of the frontal area also involved an

evolution of the head tube geometry. Its shape has been

revised and perfectly integrated with the new

lightweight fork (designed to allow an effective tyre

clearance up to 32 mm) and with the new cockpit.

Although the head set upper bearings are bigger than

the V3Rs ones, allowing the cables to run inside without

the need of the D-Shaped steerer column and

enhancing the overall front-end stability, the overall

shape has a better drag. This, of course, required a

deep surface modelling to keep the frontal area smaller

and a better aerodynamic shape factor.

New CC.01 Cockpit:

Although the V4Rs is compatible with third-party

cockpits, the overall platform has been optimized with

the new Colnago cockpit CC.01, whose drag surface

had been reduced up to 16%, compared to the cockpits

mounted on V3Rs, and at the same time the shape has

been designed and shaped as a NACA-derived profile

in order to have the minimum impact on the air flow,

which is laminar and clean while impacting the

components.

This aerodynamic evolution was carried out without

reducing the overall stiffness of the component, as

important as aerodynamic in sprint and acceleration.

Even Small Details Matter:

Furthermore, for a perfect match and lower drag, the

cockpit is offered also with the new 3D-printed,

cyclo-computer support, compatible with Wahoo Bolt

V2 (more compatibilities yet to come). This detail, on top

to the astonishing and clean aesthetics, provide also a

measurable (!) 0,75 W* saving at 50 km/h, which is

rather relevant, considering the small area of the

component.

*WAD = Weighted Average Drag (i.e. the sum of power at

different yaw angles, weighed by the probability of

occurring in such a condition).

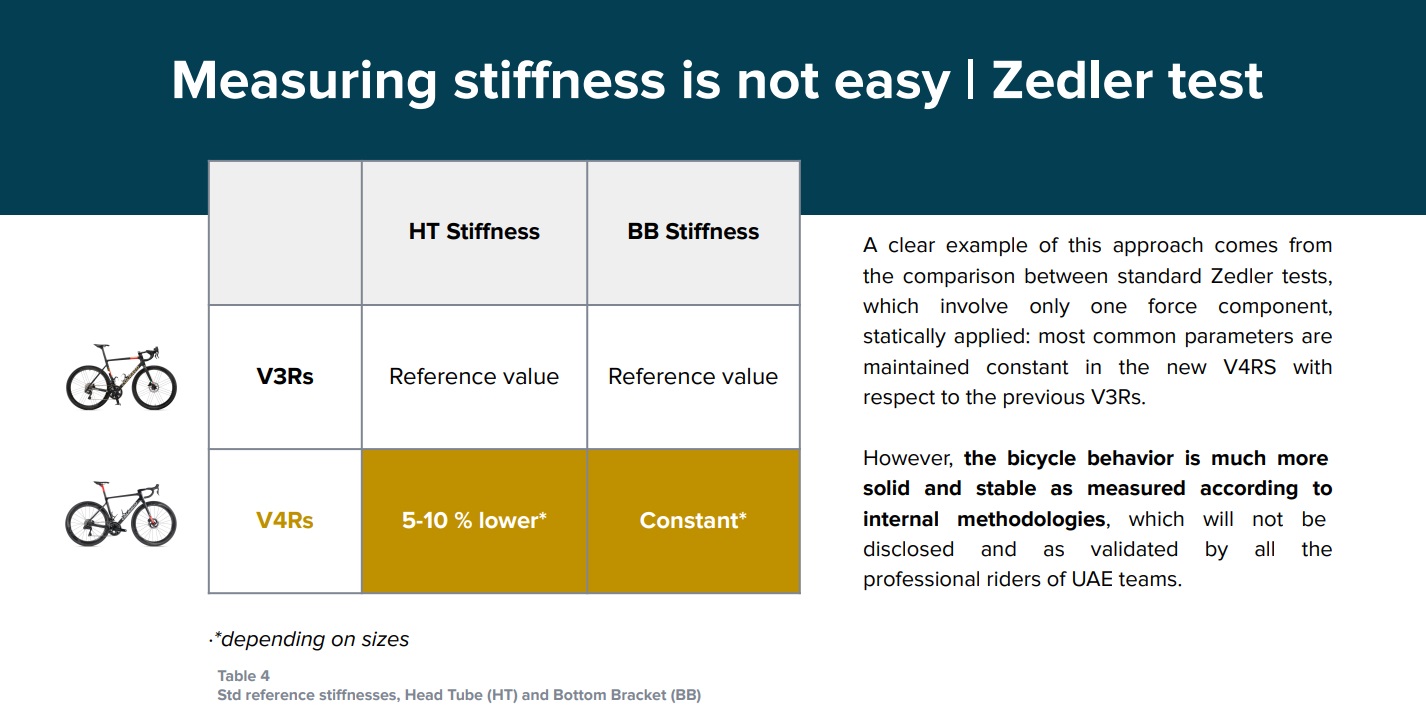

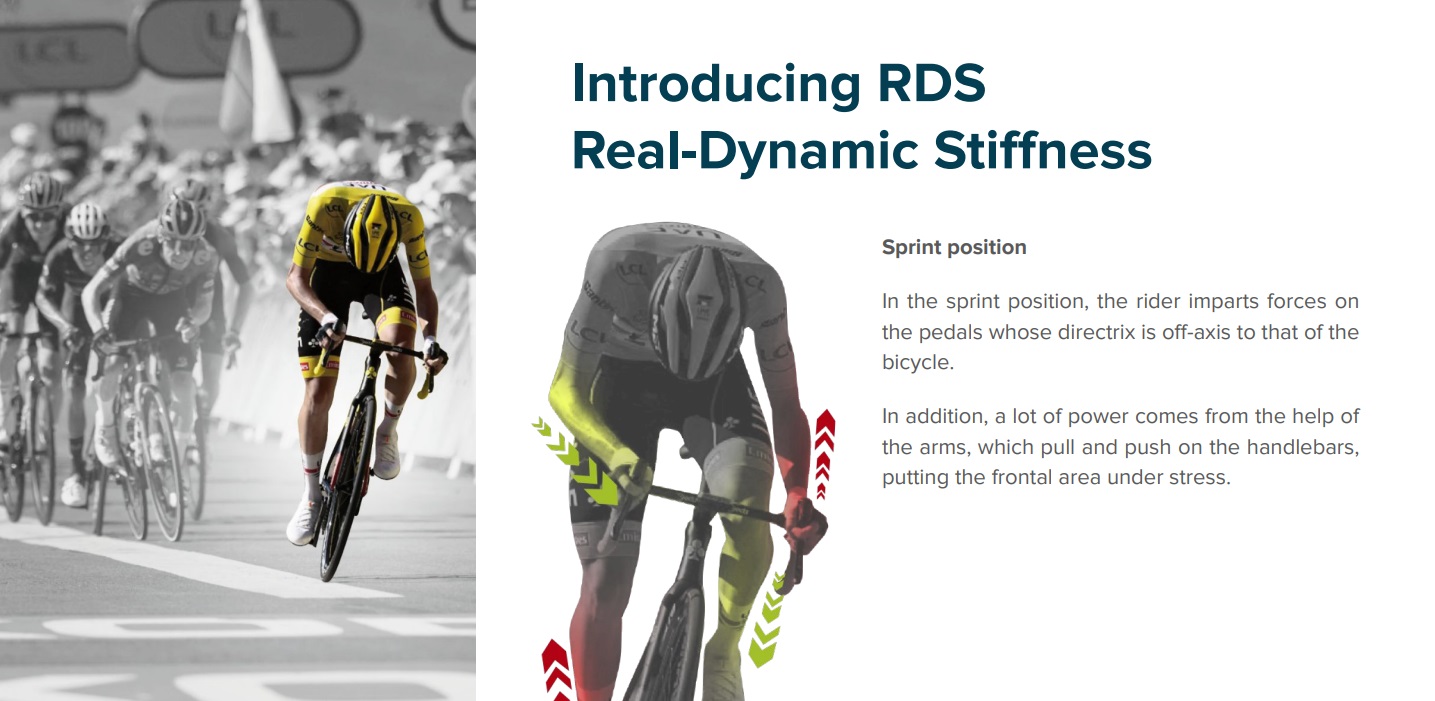

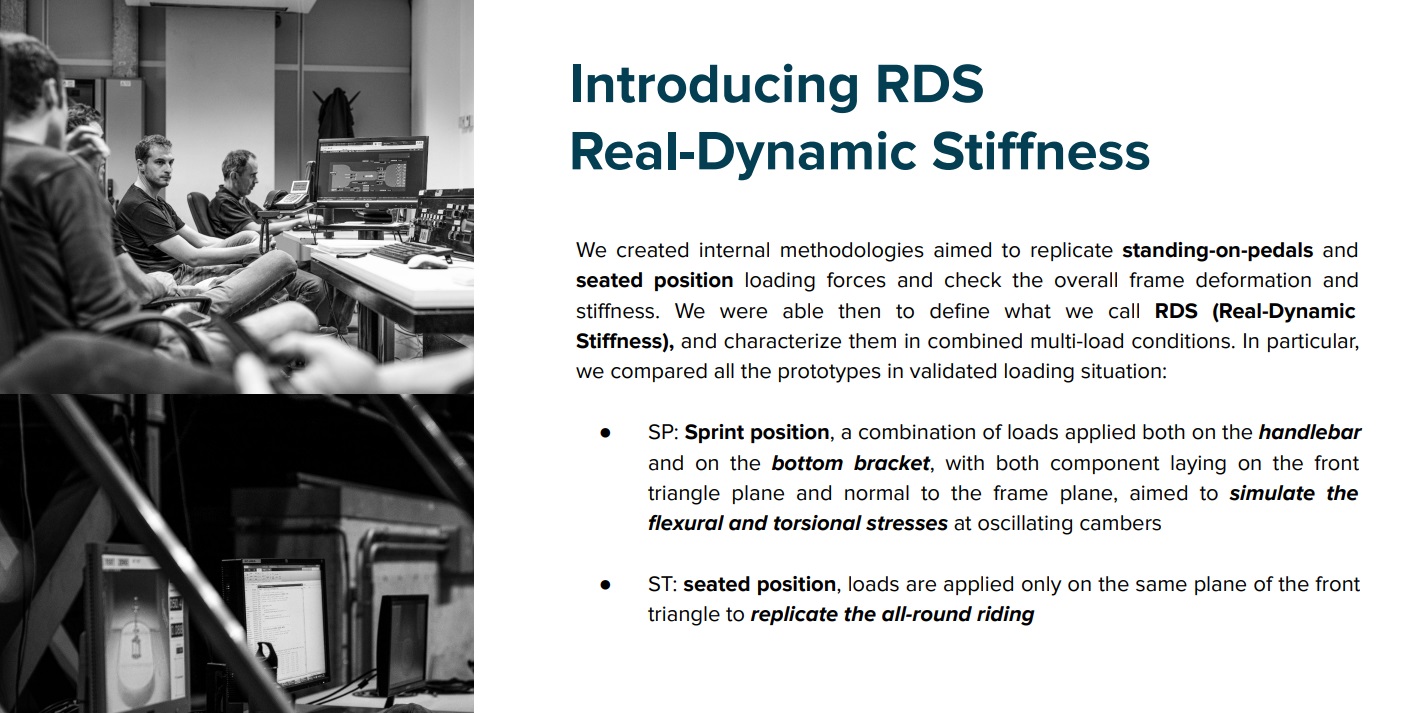

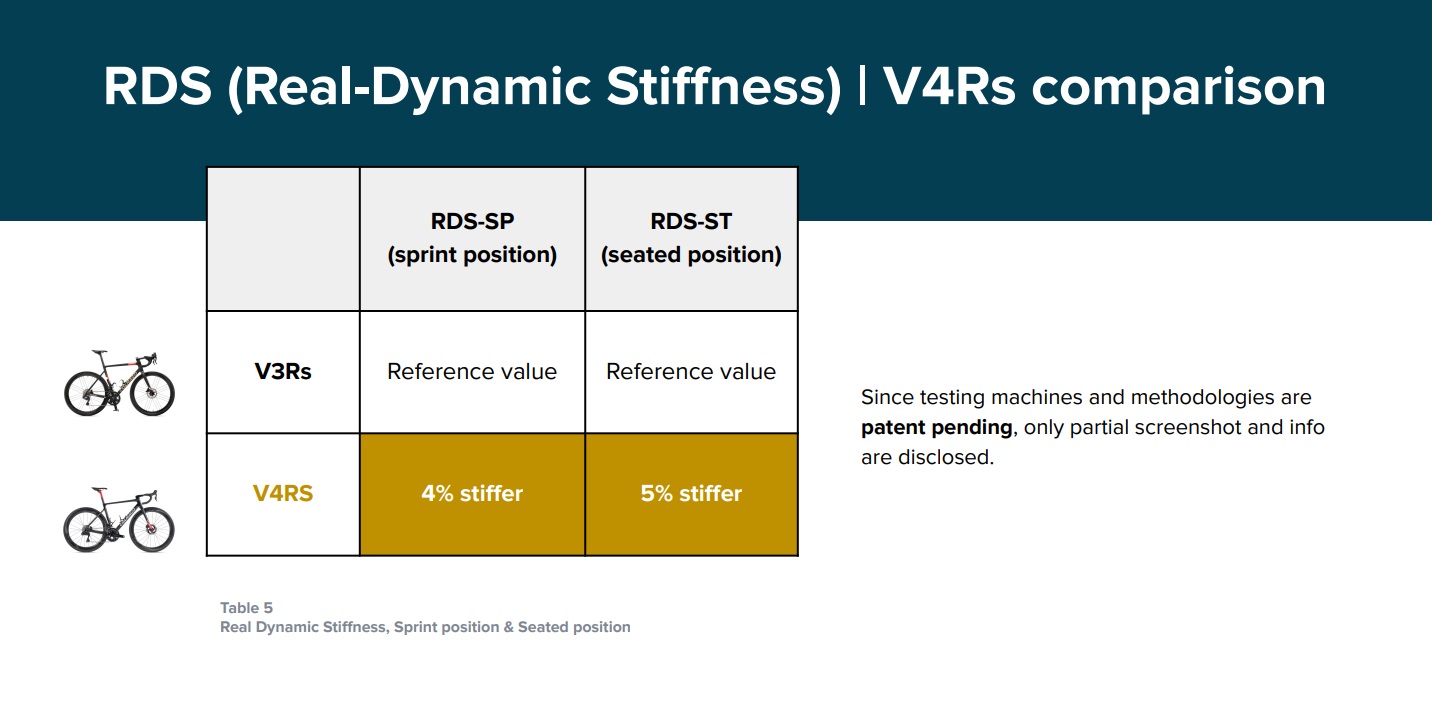

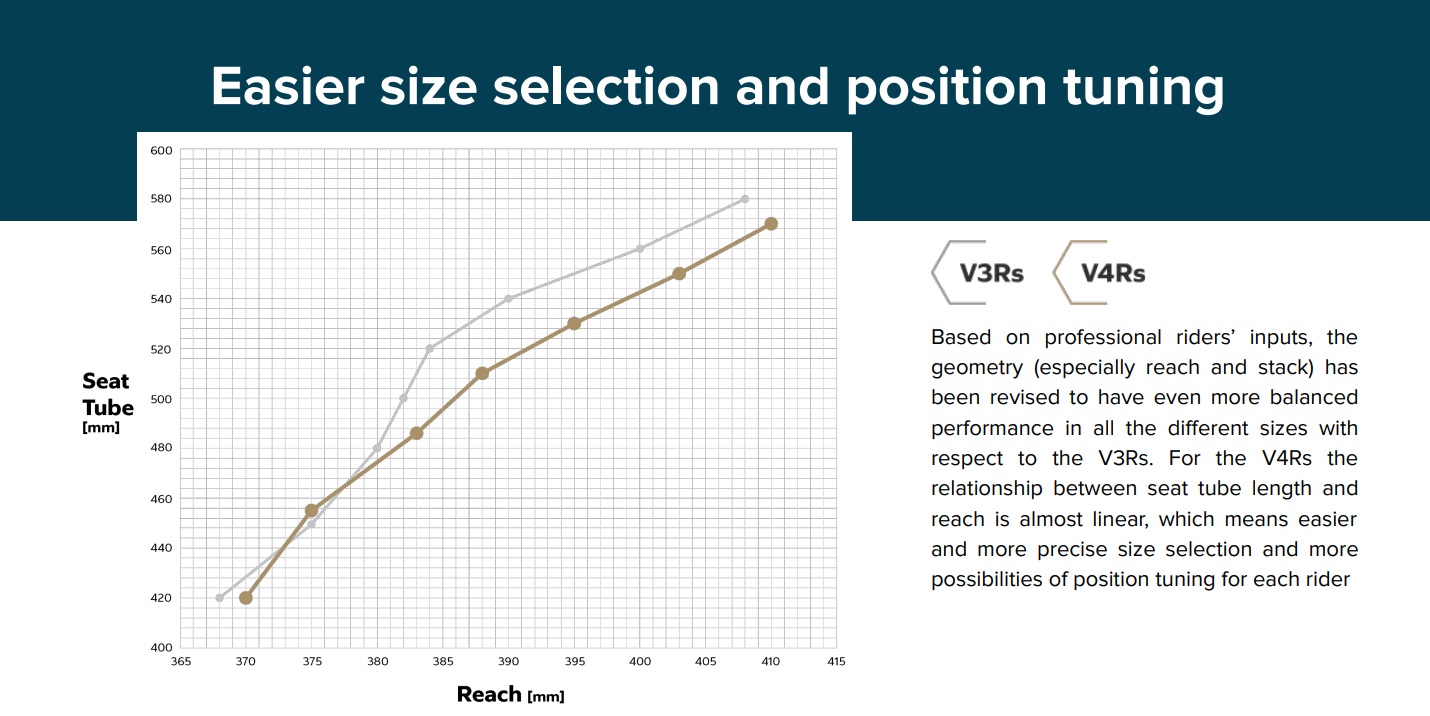

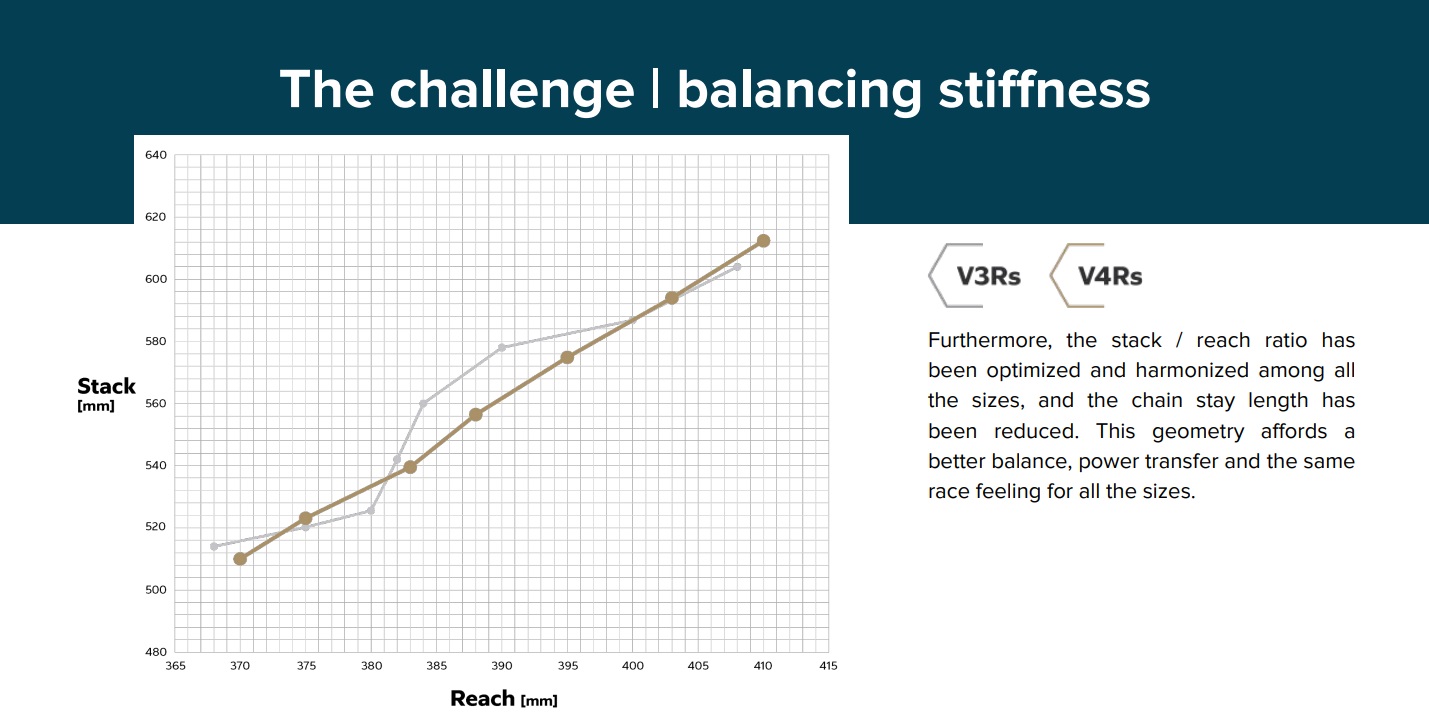

Balancing Stiffness:

During riding, a bicycle is subjected to several different

loads, acting on the whole bicycle at the same time. To

replicate and measure in indoor testing procedures able

to stress the frame in many of these conditions at the

same time, forced our engineers to develop internal

testing methodologies in order to take into account both

static and dynamic and both flexural and torsional loads.

The result is a bicycle whose all the stiffnesses are

fine-tuned and harmonized among each other to offer

the maximum performance and balance in all the

racing ultimate conditions

Innovative and racing-validated lamination:

This result has been achieved thanks to the innovative

carbon fiber lamination featured on the V4Rs. For the

ultimate racing machine, many different layups featuring

as many different stiffness matrices, have been

developed, tested and validated for professional use.

The final call was given to the riders themselves, who

were provided for the most complete and stressful

competition of the year (TDF 2022) with “Prototipo” with

the most promising layups, in order to bring the bicycle to

real limit conditions (both on cobblestones, sprint, climbs

and downhills) and provide data and feedback to our

engineers.

Crash Worthiness and Maintenance:

The overall design robustness of the bicycle can be crucial in 3-week

competitions, as well as in a classic race.

With respect to the V3Rs, the new V4Rs significantly improve the

crashworthiness of the most exposed parts which may be subjected to

impact in racing conditions.

An example is given by the completely new designed seat stays, which,

besides the more aerodynamic shape, significantly improve the flexural and

impact resistance.

The robustness of this design also minimizes the need of maintenance in,

for example, the new headset, fully provided by Ceramic Speed, which

uses SLT technology with unique solid polymer and stainless-steel

components to “remedy two of the most common causes behind bearing

failure: the absence of lubrication and grease contamination through dirt

ingress”

|

|

|